(de)Hydrogenation: feasibility of a catalyst without precious metals

The future of hydrogen technology hinges on transporting hydrogen effectively and safely. Currently, compressing hydrogen is the most common method; however, this involves significant costs and safety considerations. This is why Royal van Twist, Voyex and Fieldlab Industrial Electrification (FLIE) collaborated in 2022 to research an alternative way to make hydrogen storage safe, simple and efficient, through the deployment of a liquid hydrogen carrier, also called Liquid Organic Hydrogen Carrier (LOHC).

This study gave promising results, however, for further scale-up and roll-out of the LOHC, the consortium wants to make the concept even more attractive. This is because the process of extracting hydrogen from the liquid requires a catalyst, most of which consists of a precious metal. The increasing scarcity of raw materials could therefore be a limiting factor for the large-scale roll-out of LOHC technology. For this reason, a new consortium of Voyex, FLIE and C2CAT has joined forces to investigate the feasibility of a precious metal-free catalyst for LOHC.

The liquid carrier can largely be made from waste materials and residues from biofuels. Fossil raw materials are not needed.

Creating these systems and integrating them provides many employment opportunities.

The deployment of a liquid hydrogen tanker is an excellent fit with the infrastructure and activity already in place at the port of Rotterdam and other areas in South Holland.

LOHC is safer than diesel and has a higher hydrogen density than other liquid carriers at 66 kg of hydrogen per cubic metre.

Innovation: transporting hydrogen safely and effectively

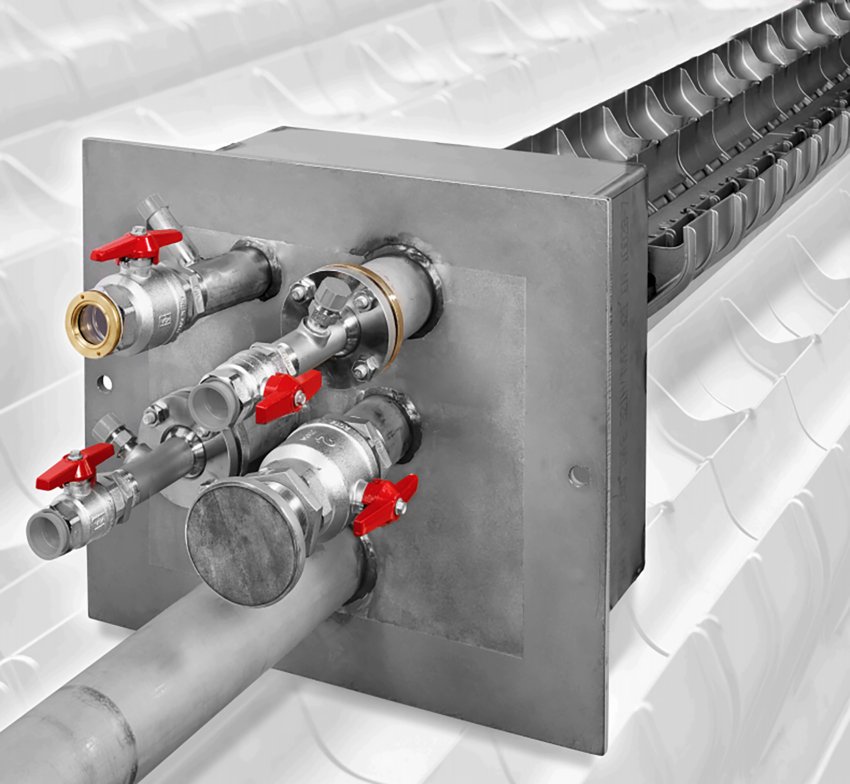

Voyex is the developer of this LOHC.Its core activities are synthesising the liquid hydrogen carrier as well as developing technology to bind (hydrogenate) hydrogen to the liquid in a circular way and discharge (de-hydrogenate) it back to where you need it. The ability to directly refuel the LOHC in heavy mobility applications provides great potential to replace diesel.

Catalysts are used to initiate and accelerate chemical reactions (in this case, water ). However, the best catalysts are often made of precious metals such as platinum, iridium, ruthenium, palladium, rhodium and a few others. These precious metals are relatively scarce and can only be mined in a few places worldwide. The growing need for precious metals in the energy transition makes them expensive and difficult to obtain.

Drastically reducing the use of precious metals is C2CAT's core expertise. They are experts in catalyst design and development, using innovative theoretical modelling and a patented way of making catalysts. Together, Voyex and C2CAT aim to reduce the cost of the LOHC chain and make the application even more attractive.

Research design

Within this feasibility study, Voyex, FLIE and C2Cat are working to develop a catalyst for (de)hydrogenation processes of liquid hydrogen carriers that eliminates or drastically reduces the use of precious metals. This is being investigated by selecting, producing and testing non-precious metals in a highly innovative way in combination with Voyex's LOHC.

For this research, candidates of metals and/or metal combinations are identified for the LOHC using theoretical models and high-performance computing. Candidate catalysts are then produced by C2Cat. These are subsequently tested and evaluated against a wide range of criteria. The results are analysed to provide a picture of both the technical and economic feasibility of the technology.

FLIE is contributing to the business development of LOHC technology during the process. For instance, the Fieldlab is working on demand articulation from the Port Industrial Complex, where import and distribution of hydrogen will play a major role in the future. In addition, opportunities are being explored for applications of hydrogenation at decentralised electrolysis facilities. Thereby, the safe and simple storage of hydrogen in a LOHC may offer opportunities to boost the entire hydrogen chain.

Next steps

Voyex already has a relatively large system 'Voyex One' in which kg tests can be carried out. The intended catalyst can be accelerated on a slightly larger scale in a next step within this system. If the same results are obtained here, a pilot project could be the next step. This would involve a synthesis plant for LOHC (+/- 300 kg pd), a hydrogenation plant (+/- 10 tonnes LOHC pd) and the capacity to realise de-hydrogenation systems (initially 10-50

Who is interested?

The project can provide insight into whether transport and storage of hydrogen via LOHC is a realistic and economically viable alternative to conventional methods such as compression. This is of particular interest to:

- Fuel suppliers/distributors

By leveraging current infrastructure with LOHC technology, they can adapt/future-proof their business model. - Parties using or supplying heavy duty mobility applications

These include: construction companies (generators, agriculture), inland and coastal shipping and transport companies (long-distance trucking).

About FLIE

FLIE is a joint initiative of Deltalinqs, FME, Port of Rotterdam, InnovationQuarter and TNO and is closely supported by the Province of South Holland, the Municipality of Rotterdam and the ERDF grant.

Does your organisation have sustainability ambitions and would you like to explore the possibilities of electrification? Or do you provide an electrification solution and would you like to get in touch with end users and other important stakeholders? Then contact us. We will be happy to help you!