Electrification - Power -to-Hydrogen

From electrification to hydrogen integration in your business process

Hydrogen, especially when produced sustainably, offers a powerful alternative within the electrification strategy of companies in chemicals, refining and heavy industry. Through Power-to-Hydrogen, you convert renewable electricity into hydrogen, which can then serve as a feedstock, energy carrier or buffer in your process chain.

At FLIE, we support companies that want to make the step from exploration to implementation. With knowledge, test facilities and a strong network in the Rotterdam port-industrial ecosystem, we help integrate hydrogen effectively into your business operations.

In this article, we take you through the practical steps to apply Power-to-Hydrogen in your business processes.

Power-to-hydrogen: what role does hydrogen play in your process?

Hydrogen can add value to industrial processes in several ways. The deployment depends on business activities and sustainability goals:

1. Hydrogen as a feedstock

In the chemical industry and refineries, hydrogen has been an essential feedstock for decades. Think of ammonia production, methanol synthesis or hydrotreating fuels. By replacing grey hydrogen (from fossil gas) with green hydrogen, you directly reduce CO₂ emissions from these processes.

Application example: A refinery using hydrogen for desulphurisation can save tens of thousands of tonnes of CO₂ annually by electrifying its hydrogen production.

2. Hydrogen as an energy carrier

Hydrogen can serve as a storage medium for renewable electricity. At times of excess wind or solar energy, electricity can be converted into hydrogen, which can later be used for heat, electricity or as a feedstock. This makes hydrogen interesting for companies that:

- Want to accommodate peaks in energy demand without grid expansion

- Seeking buffers for fluctuating renewable resources

- Want to achieve sector coupling between electricity, gas and industry

Application example: A chemical company with its own wind turbines converts excess power into hydrogen for use in production processes during windless periods.

3. Hydrogen as a reducing agent

In steel and metal production, coke (from coal) has traditionally been used to reduce iron ore. Hydrogen can take over this role, with water vapour as the only by-product instead of CO₂. This opens the way to climate-neutral steel production.

Application example: Direct Reduced Iron Ore Reduction with Hydrogen (DRI) is emerging as an alternative to the traditional blast furnace.

4. Hydrogen in Power-to-X chains

Hydrogen is the building block for many synthetic products:

- E-fuels: Combination of hydrogen and CO₂ produces synthetic paraffin, diesel or methanol

- Ammonia: Hydrogen and nitrogen form green ammonia, usable as fertiliser or energy carrier

- Methane: Methanisation creates synthetic natural gas (SNG)

These Power-to-X applications present opportunities for companies looking to respond to the growing demand for climate-neutral fuels and chemicals.

Featured projects

Technical operation

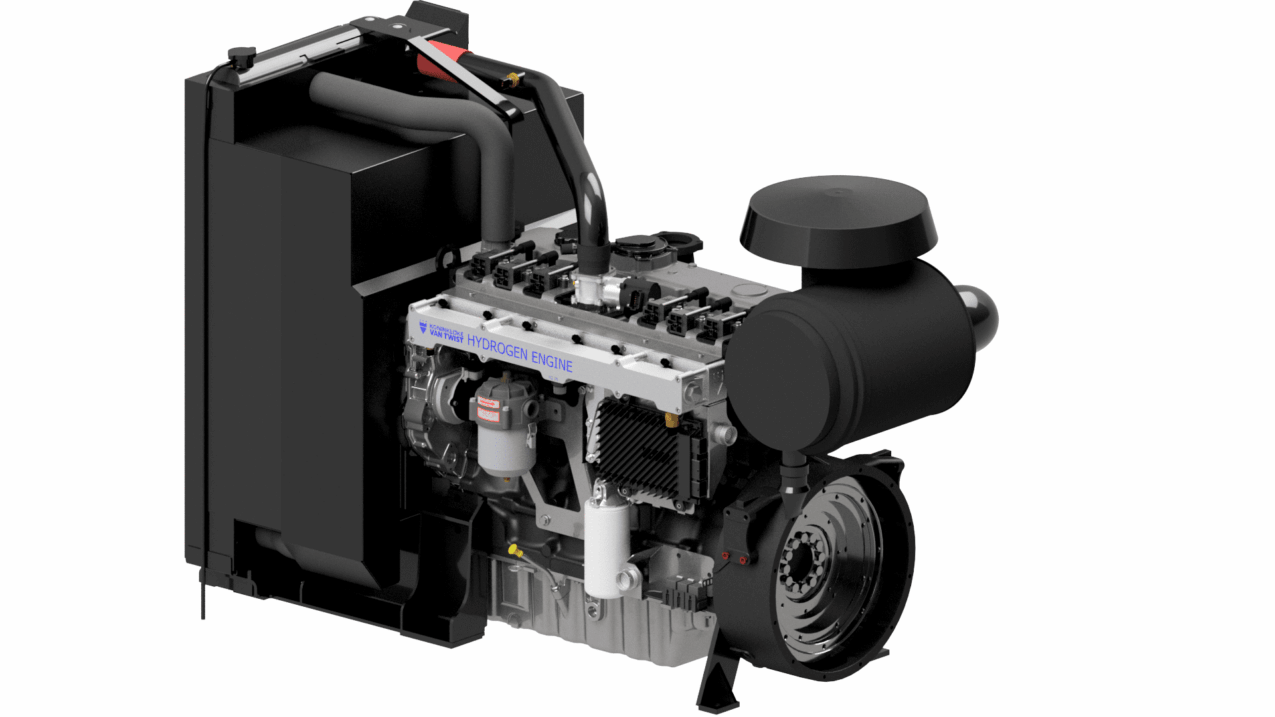

In Power-to-Hydrogen, electricity is used to split water (H₂O) into hydrogen (H₂) and oxygen (O₂) via an electrolyser. There are different types of electrolyser, such as PEM (Proton Exchange Membrane) and alkaline types, each with its own characteristics in terms of efficiency, cost and pressure of the hydrogen produced. The choice of technology depends on the company's specific situation: availability of waste heat, flexibility needs, scale and investment budget.

Four steps to successful hydrogen integration

Hydrogen integration requires a structured approach to ensure a good fit between technology, safety, infrastructure and business case. The four steps below help to purposefully assess hydrogen applications within your operation and translate them into a feasible and scalable deployment in your production environment.

1. Demand analysis: how can hydrogen strengthen your process?

A successful implementation starts with identifying your hydrogen needs:

- Current hydrogen consumption: Are you already using hydrogen? How much and for what processes?

- Potential new applications: are there processes in which hydrogen can replace fossil fuels or raw materials?

- Demand pattern: Is your hydrogen demand constant or variable? Can you build in flexibility?

- Purity requirements: What quality of hydrogen does your process require?

This analysis determines the sizing of electrolysis plants and the required storage capacity.

2. System integration: from electrolyser to process application

Hydrogen production via electrolysis should fit seamlessly into your existing infrastructure:

Electrical infrastructure

- Is your grid connection adequate for the electrical power of the electrolyser?

- Can you link your own generation (PV, wind) for maximum carbon reduction?

- How do you manage peaks and flexibility without overloading the grid?

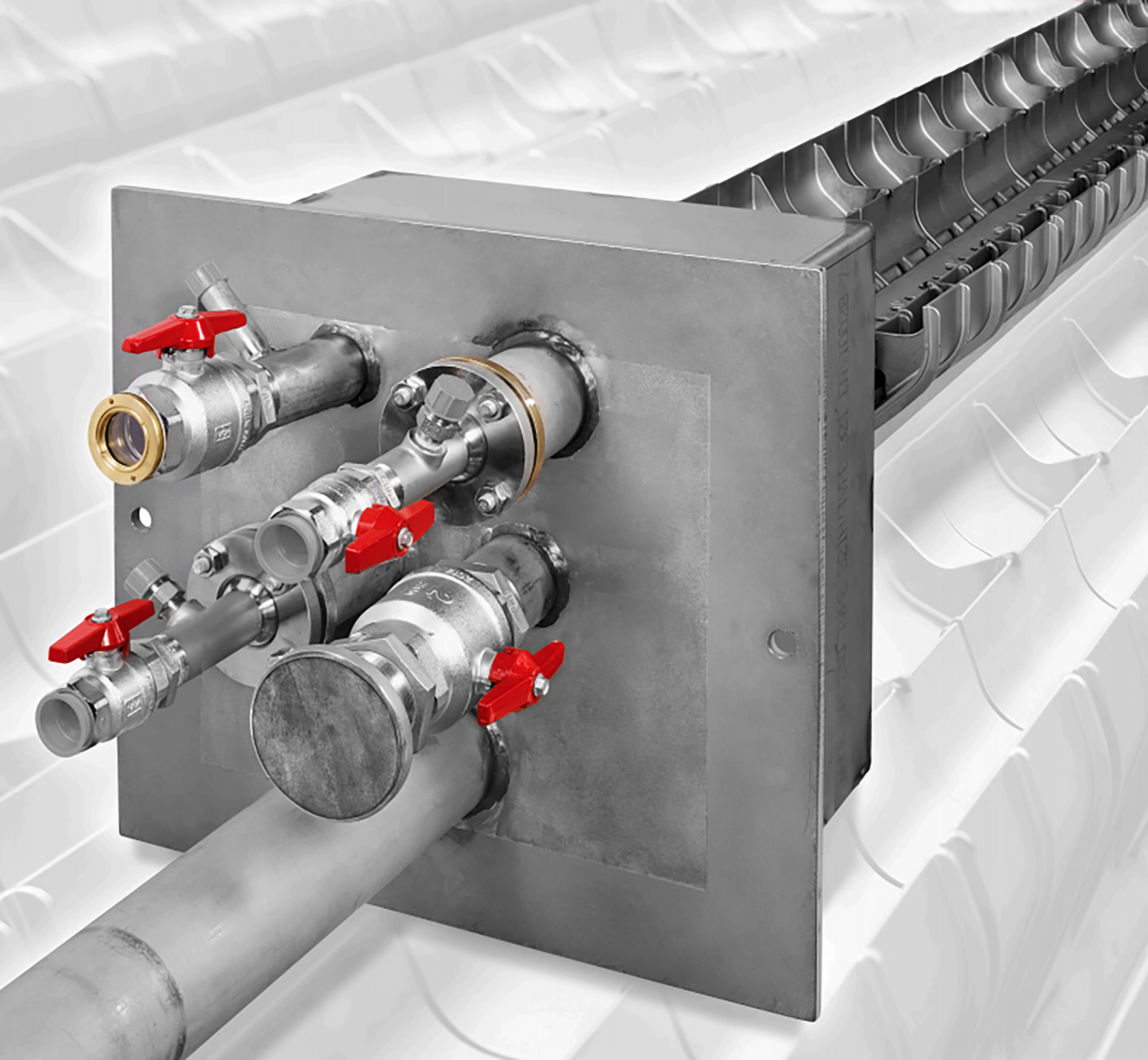

Hydrogen infrastructure

- Compression: what pressure does your process require and which compression technology suits it?

- Storage: buffer tanks or underground storage for seasonal buffering?

- Transport: pipes, tube trailers or conversion to other carriers (ammonia, LOHC)?

- Safety: hydrogen requires specific certification, detection and safety measures

Process integration

- How do you link hydrogen power to existing reactors or combustion systems?

- What adjustments are needed to process equipment and control systems?

- Can the oxygen released by electrolysis also be put to good use?

3. Business case: calculating green hydrogen

Green hydrogen is currently more expensive than grey hydrogen from natural gas. A conclusive business case therefore requires smart maths:

Cost drivers

- Electricity price: 60-80% of production cost comes from electricity

- Investment costs: electrolysers, compression, storage and safety facilities

- Operational costs: maintenance, water, ancillaries

Financial benefits

- CO₂ savings: avoidance of ETS costs and carbon taxes

- Grants such as SDE++, OWE, IMKE, DEI+, NIKI and more

- Green certification: products with low carbon footprint get market advantage

- Future-proofing: anticipating tighter regulations and demand for green products

Flexibility as a revenue model

- Demand response: electrolysers can help balance the grid

- Arbitrage: producing during hours with low electricity prices

- Grid stability: electrolysers as flexible power can generate revenue through balancing markets

FLIE can support In developing a robust business case, including scenario analyses and grant advice.

4. Scaling up and ecosystem: stronger together

Hydrogen projects are rarely standalone initiatives. Success requires collaboration:

Value chain integration

- CO₂ sources: for Power-to-X chains, you can collaborate with companies that capture CO₂

- Buyers: who can buy your hydrogen or derivatives?

- Infrastructure: connecting to hydrogen networks such as the H2 Backbone Rotterdam

Knowledge development

- Pilots and demonstrations: test technology at scale before making full investments

- Research projects: develop new applications together with TNO, universities and HBOs

- Best practices: learn from forerunners and share knowledge

Funding

- Public-private partnerships: use European and national funds

- Consortia: join forces with partners for larger projects

- Risk sharing: reduce individual risks through cooperation

The Rotterdam port industrial area offers a unique ecosystem with CO₂ resources, renewable energy, existing infrastructure and innovative partners.

How FLIE can support you

FLIE offers a hands-on approach to integrate Power-to-Hydrogen into your organisation:

- Exploration: we help you carry out feasibility analyses, including business cases and risk assessment.

- Pilots: together, we can set up pilot projects, for example with small-scale electrolysers and test infrastructure.

- Power scaling: we connect you with technology partners for scale-up and integration into your existing process infrastructure.

- Funding and subsidy: we support in identifying relevant grants and (regional) support programmes.

- Network: through FLIE, you get access to other companies, knowledge institutions and investors active in hydrogen projects.

Power-to-Hydrogen offers a strategic route for manufacturing companies to green, increase flexibility and enter new markets. By converting renewable electricity into hydrogen, you not only create a low-CO₂ energy carrier, you build a sustainable raw material chain.

Interested?

Take the step towards a sustainable heat supply today

Want to know more about hydrogen integration in your business environment? Want to start a feasibility study, or develop a pilot with partners? Then take contact FLIE. We help you go from idea to implementation.

Together, we are accelerating the electrification of industrial processes in South Holland and building a future-proof industry.

Getting started with electrification?

The Fieldlab Industrial Electrification

The Fieldlab Industrial Electrification consists of two main components:

- On the one hand, a 'Fieldlab Hub' where work will be done to test and scale up new technologies in the value chain present. Cooperation will be sought with industry and research and educational institutions in the region. There is also a special focus on cooperation with potential value chain partners and space for realising business cases.

- The second part of the Fieldlab consists of on-site demonstration sites at companies where these new techniques can be tested and applied in practice.

Getting started with electrification? Then click here.