New liquid hydrogen carrier combined with waste heat offers opportunities for safe and efficient hydrogen storage

Hydrogen is in the news almost daily. Green hydrogen - made from water and renewable electricity - is a promising fuel for various applications in industry, chemicals, heavier mobility and in a broader sense for energy storage and transport. The biggest challenge at the moment is the safe use of hydrogen and its transportation. This is because it is currently still necessary to compress or liquefy hydrogen to high pressures so that you can actually transport large quantities. Royal van Twist (KvT), Voyex and Fieldlab Industrial Electrification (FLIE) have jointly researched an alternative way to make hydrogen storage safe, simple and efficient, by deploying a liquid hydrogen carrier. Voyex is developing this hydrogen carrier, also called LOHC-Liquid Organic Hydrogen Carrier technology. Basically, it comes down to synthesising a specific liquid, binding hydrogen gas to that liquid and then extracting it where you need it. The liquid is used in a circular fashion to be charged and discharged with hydrogen each time.

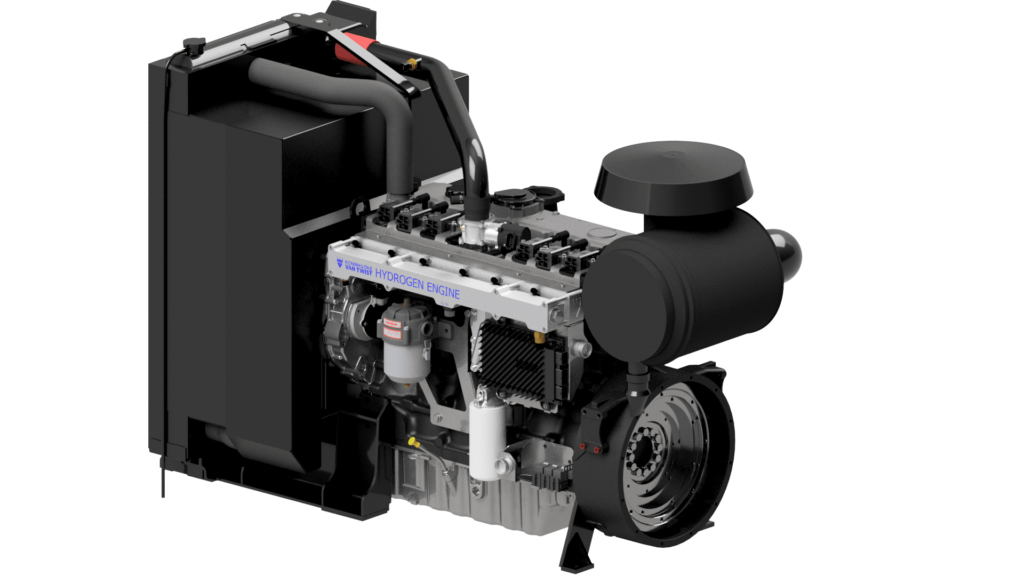

Royal van Twist has built a 100% hydrogen generator and sees the potential benefits of LOHC to supply the generator with hydrogen. This is because the liquid is safer than diesel and can store a lot of hydrogen in itself. For instance, it can store 59 kilograms of hydrogen per tonne. Since it is a liquid, it can be fitted into supply chains in the same way as we are used to now. It also requires a relatively small system to extract the hydrogen, making it easy to fit into or close to the ultimate hydrogen user. Extracting the hydrogen from the liquid does require heat and that is precisely what KvT's hydrogen generator produces as 'residual power' alongside electricity. The main focus of the feasibility study was to see if sufficient heat is available and what an integrated system would look like.

Results

The feasibility study showed that almost all the heat is available to extract the hydrogen from the carrier. Only 4% of the hydrogen would be 'sacrificed' for additional heat. In addition, it has been shown that the system remains compact enough to be easily installed next to KvT's generator. Given the high energy density of the liquid carrier, energy can be provided for several days in standard storage tanks. Thus, with one ten cubic metre of storage, you can store 20 megawatt hours of energetic energy. The technical attractiveness of the concept has thus become apparent and provides all the necessary input to investigate the further (business) case for an initial prototype.

Next Steps

These insights have highlighted how LOHC connects to combustion engine technology, such as KvT's generator. Now there is a need to develop a system that delivers hydrogen to a generator in practice. In doing so, it is very important to achieve heat integration to reinforce the study carried out. In a further future, the LOHC technology could possibly be scaled up further, for example through a pilot plant, in cooperation with FLIE.

About FLIE

FLIE is a joint initiative of Deltalinqs, FME, Port of Rotterdam, InnovationQuarter and TNO and is closely supported by the Province of South Holland, the Municipality of Rotterdam and the ERDF grant.

Does your organisation have sustainability ambitions and would you like to explore the possibilities of electrification? Or do you provide an electrification solution and would you like to get in touch with end users and other important stakeholders? Then contact us. We will be happy to help you!