Successful completion of SES project with AMELA

Smart energy management in practice

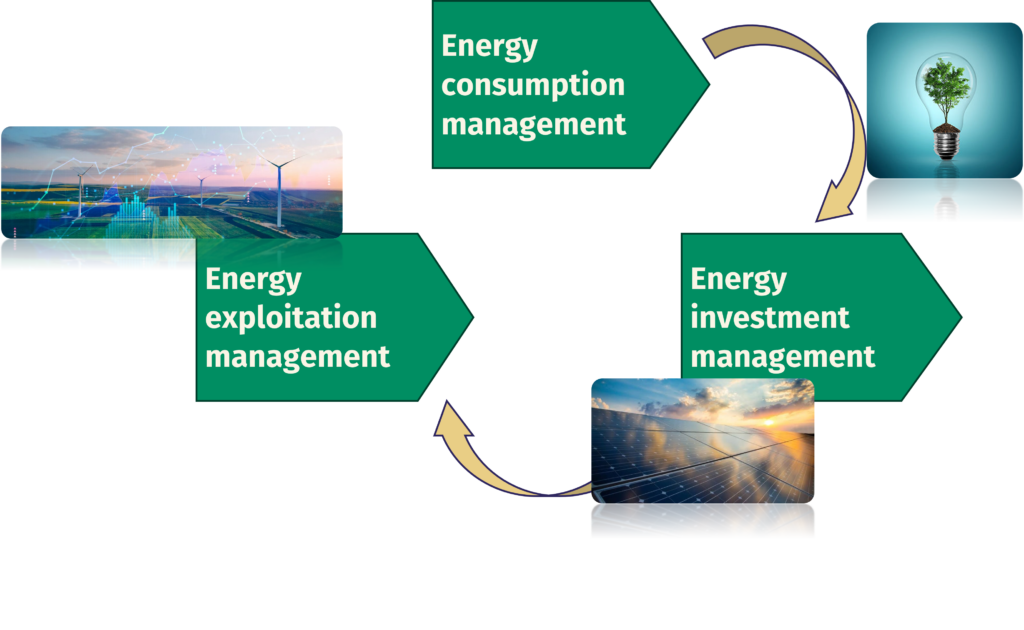

In 2024, AMELA and Fieldlab Industrial Electrification (FLIE), with the support of the Smart Energy Systems (SES) grant from the municipality of Rotterdam, launched an ambitious project. The aim: to demonstrate how smart energy management can help industrial companies optimise their energy consumption and operate more sustainably. The project focused on the development and validation of AMELA's innovative Energy Management in 3 Steps (3-EM) method, which optimises energy consumption, investment decisions and operation.

Practical application: Coatinc as a pilot case

An important part of the project was the collaboration with Coatinc Alblasserdam BV, a specialist in galvanisation and steel preservation. Coatinc had already taken steps towards sustainability, such as heat recovery and the installation of new burners. However, the big question was: what is the best next step? Electrification, hydrogen, or some other solution?

The 3-EM method was used to investigate how energy consumption per kilogram of product could be systematically reduced. In the process, several key insights emerged:

- Data-driven insights: Through pattern recognition (machine learning algorithms) on historical energy and production data, it became clear that fluctuations in production rates directly affect energy consumption. More even production planning can lead to significant savings.

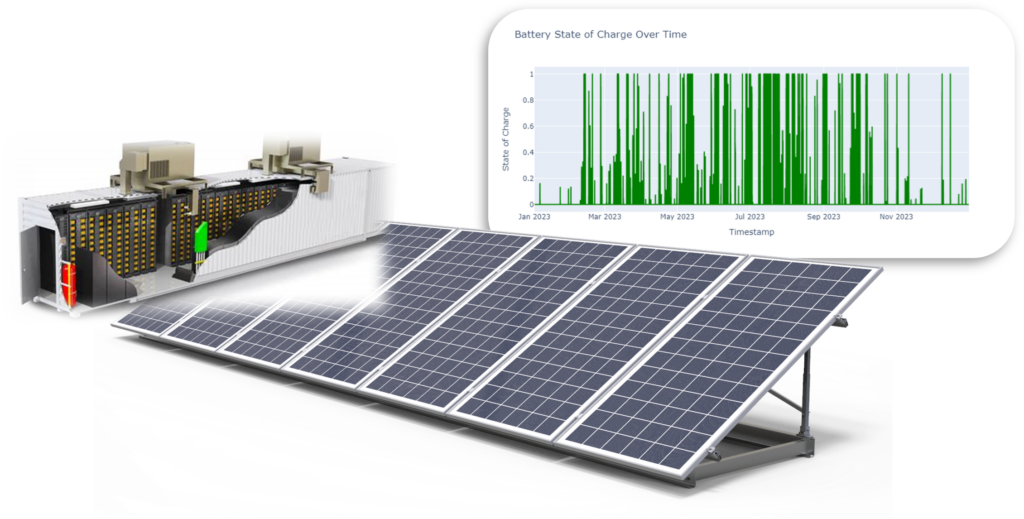

- Simulations of sustainability options: Several investment scenarios were run through, including electrification, solar deployment and battery storage. The best strategy was found to be a combination of 'base load' electrification and smart deployment of batteries, when there is a surplus of solar energy.

The strength of 3-EM lies in its ability to quickly calculate various sustainability options.

A data-driven approach makes decision-making more transparent and reduces investment uncertainty.

The method can greatly improve the current practice - in which many manual Excel calculations are required -.

Expansion into the chemical industry

In addition to the pilot at Coatinc, the 3-EM method was also tested at a chemical company. Here, Machine Learning was applied to predict and optimise the energy consumption of compressors. The first results are promising and show that the method is widely applicable within various industrial sectors.

Cyber Security Analysis

An essential part of the project was the cyber security analysis, carried out in line with the ISO 27001 standard. AMELA conducted an in-depth risk analysis and implemented measures to ensure the security of the platform. This included:

- Threat modelling, in which potential vulnerabilities in the system were identified and addressed.

- Data encryption and access management, to protect sensitive business information.

- Implementation of security protocols, ensuring that the platform meets the highest industry standards. These measures ensure that companies not only save energy, but also work with a safe and reliable tool.

Market validation and feedback

The project demonstrated that smart energy investments can be better substantiated using data and simulations. This was confirmed by interviews in a market survey. Their main feedback:

- The strength of 3-EM lies in its ability to quickly calculate various sustainability options.

- A data-driven approach makes decision-making more transparent and reduces investment uncertainty.

- The method can greatly improve the current practice - in which many manual Excel calculations are required -.

Future vision for platform

AMELA has ambitious plans to further develop and scale the platform into a widely deployable tool for the industry. The main focal points are:

- Three new pilot projects: To further validate the method in different sectors.

- Onboarding of technology partners: AMELA aims to link multiple renewable energy solution providers to the platform. their specific plant is modelled within the 3-EM platform's existing data structure and can then be automatically linked energy investment simulations.

- Net congestion Advisor tool: The platform will be extended with a module that helps companies better match their energy consumption with available grid capacity, which is essential in today's energy market.

Want to know more about this project or the possibilities for your organisation? Get in touch with us!